Schedule 80 stainless steel pipes are designed for use in high pressure applications with walls that're thicker than Schedule 40 pipes to increase their strength and longevity.They are often used in industries like chemical processing and construction where sturdy and corrosion resistant piping systems are crucial to operations.

Wall Thickness: Schedule 80 pipes have increased wall thickness compared to Schedule 40 pipes, providing enhanced pressure resistance.

Material Grades: Common grades include 304 and 316 stainless steel. Grade 316 offers superior corrosion resistance, making it suitable for marine environments and chemical processing applications.

Dimensions: The dimensions vary based on nominal pipe size (NPS). For example, a 1-inch NPS Schedule 80 pipe has an outside diameter of 33.4 mm and a wall thickness of 4.55 mm.

Applications:

Chemical Processing: Due to their resistance to corrosion, Schedule 80 stainless steel pipes are ideal for transporting aggressive chemicals.

Water Treatment: Their strength and resistance to corrosion make them suitable for water treatment facilities.

Construction: Used in structural applications where high strength is required.

Availability

Stainless steel pipes with a Schedule 80 rating come in various size and length to suit project needs. Suppliers provide these pipes in welded or seamless versions. Offer custom lengths and finishes well.

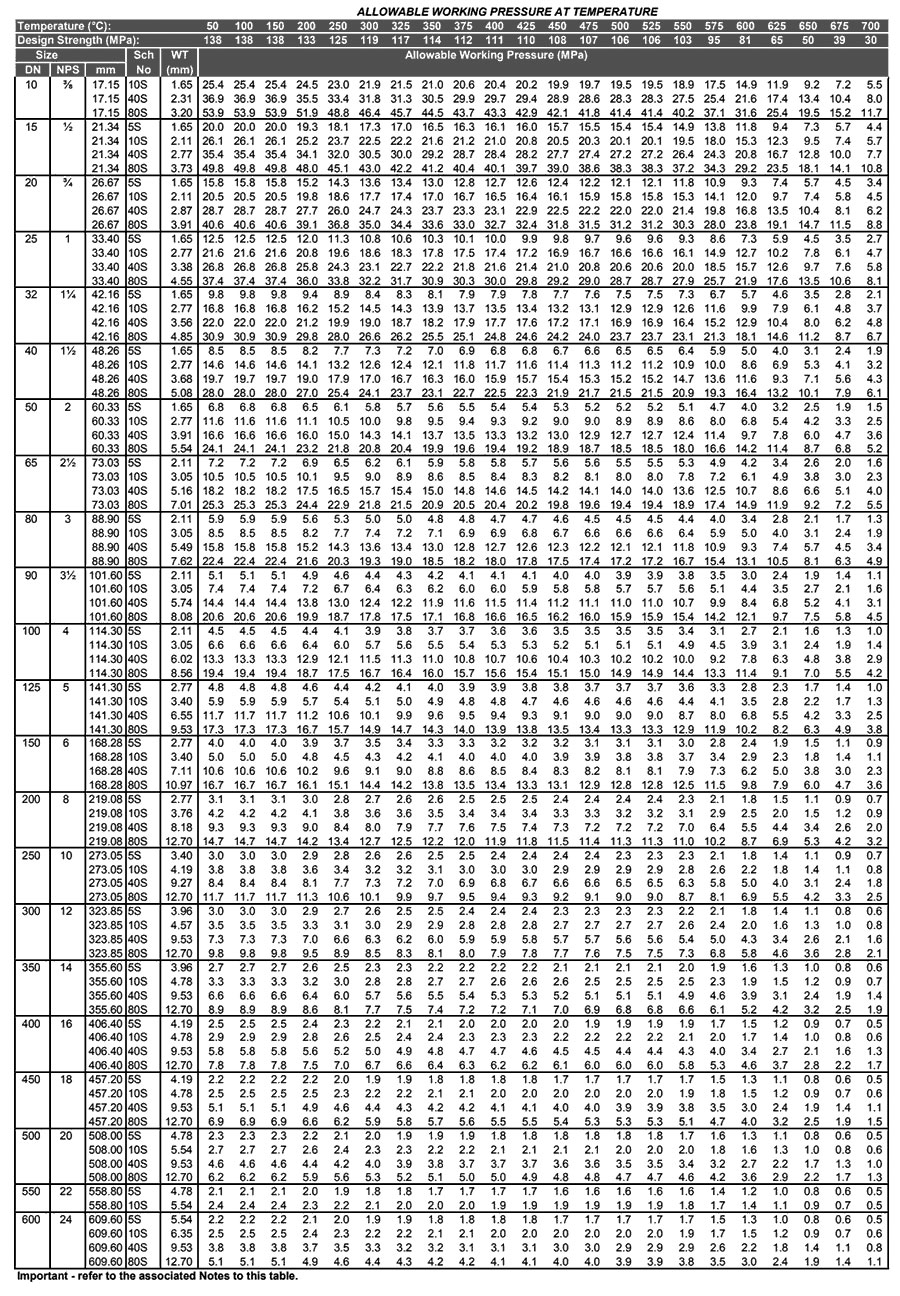

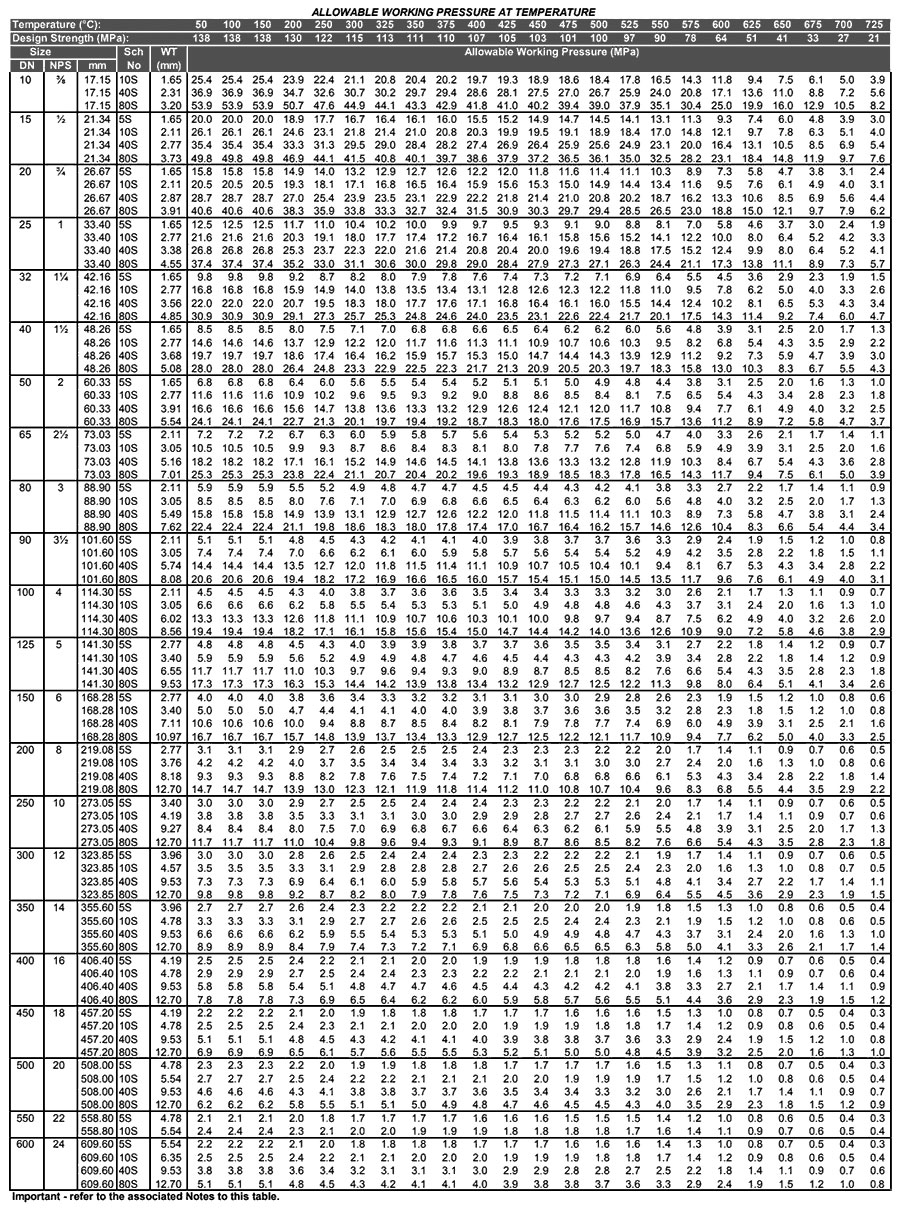

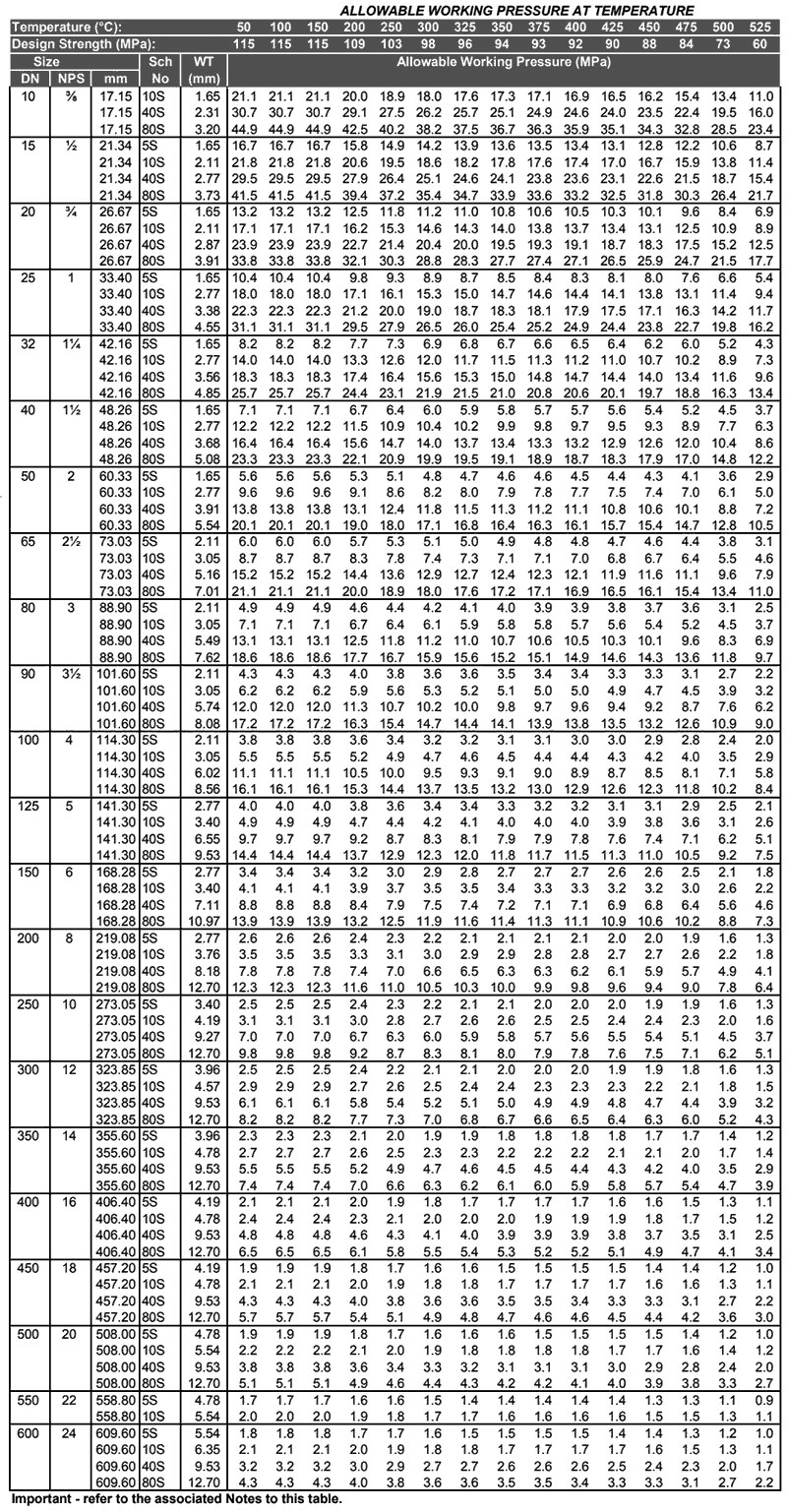

Please consult the charts from manufacturers and industry standards for measurements of dimensions and weights as well as pressure ratings.

When choosing Schedule 80 stainless steel pipes for your needs make sure to take into account factors such, as the use, the surrounding conditions and how well they work with materials to guarantee top notch performance and durability.